Applications

Offerings >> Hydrogen Gas Detector >> Applications

Hydrogen Sensing Technology ~ Sensing Principle

The Proprietary Sensor is a solid-state electrochemical sensor based on a solid electrolyte and a proprietary solid reference electrode (Indian Patent No. 252998 w.e.f 14/06/2007).

These Proprietary Sensors essentially are galvanic cells constituted with two hydrogen electrodes, one of which is fixed and the other variable.

The Patented Technology has a novel reference electrode system with a unique contacting mechanism for the contact between a reference electrode and H+ ion conducting solid electrolyte for an improved solid-state electrochemical hydrogen sensor.

The Proprietary Sensor measures the direct partial pressure of hydrogen in any gaseous fluid environment.

It is specific, selective and intelligent to Hydrogen and does not get permanently damaged upon exposure to the high concentration of hydrogen, allowing a very wide, industry-leading measurement range.

Hydrogen Sensing Technology ~ Superiority over Competition

The major issues faced by Semiconductor and Catalytic Pellistor technology are

Limited range only up to 4% H2 (0%-100% LEL)

The sensor gets damaged beyond repair, upon exposure to a high concentration of H2

Warranty may not be exercisable if exposed to a higher concentration of H2

Susceptible to cross-sensitivity and interference from other gases

Catalytic Pellistor – low sensitivity & low resolution

Semiconductor – very low range

Our technology commits to solving all the above issues.

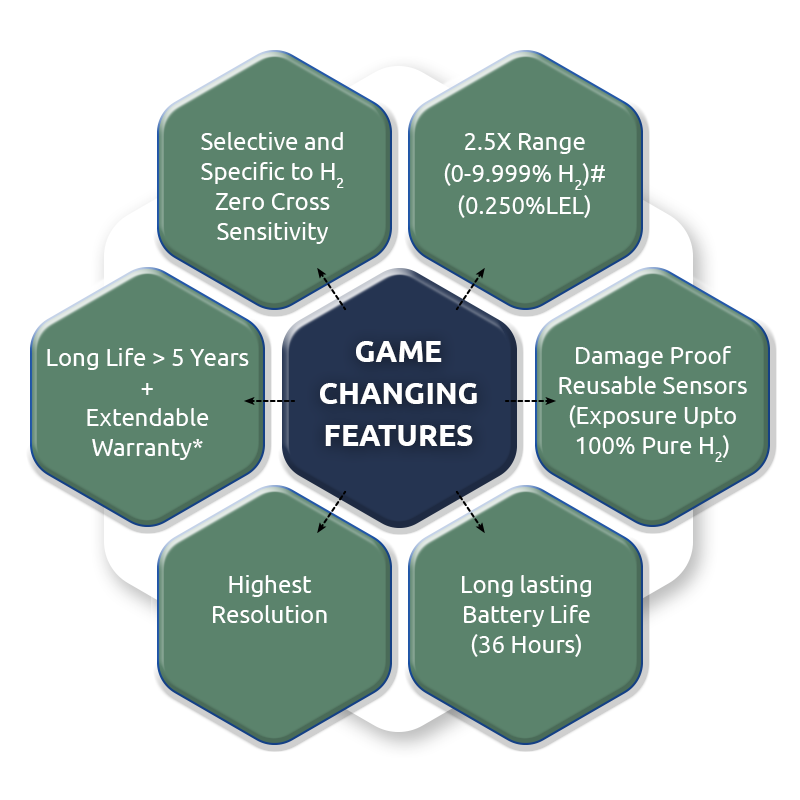

Hydrogen Sensing Technology ~ Game Changing Features

The advantages offered are

Can withstand exposure to even 100% pure Hydrogen

Widest sensing range

No worry of damage in taking a detector close to the source of leak

Damage Proof sensor has a long life and higher value for money

Low maintenance cost and quick turnaround time for calibration

No need for pre-mature panic action as the sensor has a very wide range and user-selectable multilevel alarms

No false alarms due to cross sensitivity

User friendly calibration using Gas Calibration Kit

Standard 1 Year warranty + Extendable warranty + AMC

Facts about Hydrogen

Hydrogen is the lightest element on the planet and makes up about 75% of the elemental mass of the entire universe.

It is very difficult to detect as it is odourless, colourless and tasteless.

It poses an extremely high explosion risk as it is highly combustible in mixtures ranging from 4% (Lower Explosive Limit – LEL) to 75% (Higher Explosive Limit – HEL) in Air.

It can ignite with very low energy input like an electrostatic spark from a human.

It travels at a speed of 1920 m/s, nearly 5.6 times the speed of sound.

Being the lightest element, it travels vertically upwards at great speed and accumulates in pockets at the ceiling surface, where it may form an explosive mixture with air.

Due to the risks associated with hydrogen, it is essential to locate hydrogen gas leaks and monitor the levels of hydrogen to ensure its concentration remains safely below the LEL.

Area Monitoring

To continuously monitor the levels of hydrogen in an enclosed space like battery rooms, hydrogen storage rooms, areas containing hydrogen carrying pipeline and hydrogen transacting equipment.

Leak Location

In order to locate the exact source of a leak, a portable hydrogen leak detector is necessary to pinpoint the leak and take corrective action. Leak Location can be classified into Safety Leak Location and Leak Integrity Testing.

Smart Asset Monitoring

Critical and high-value assets like Oil-Cooled Transformers used for transmission and distribution of electricity can be safeguarded through continuous online monitoring of hydrogen.

Applications